Immersed with the designers of Le Slip Français !

If you have read the interview with Matthieu Coquelin, then you already know the story of la Confection du Coglais. I now suggest you follow me behind the scenes of the making of Le Slip Français swimsuits. Grab a seat next to the seamstresses. It is definitely worth a visit!

Here, we are in one of the most beautiful French factories for high-end swimsuits. The company was elected in 2016 as a Company of Living Heritage. A recognition from the State to certify the excellence and reward 47 employees who have a unique savoir-faire !

Here, we manufacture for big luxury brands like Erès, and other brands whose names I’m not allowed to mention ! Shhhhhh !!!!! And then luckily for me, there’s also Le Slip Français who decided to join the swimsuit industry.

The right collaboration, the training of employees and its unique savoir-faire. That’s what made the turnover of la Confection du Coglais from 42.000 euros in 2012 to 500.000 euros in 2017!

So here are the amazing steps to making swimsuits! Starting from the storage of the material and the cutting.

You still believe in paper draping? Wake up, we’re in 2017. Here everything arrives by mail and there is a software that draws the steps to follow. Let’s go to the section where they do the cutting. Matthieu Coquelin, the head of the company, tells us that lycra, polyamide and elastane are very delicate materials.

They are living material that change a lot in on the heat. After they arrive, they must be put to rest from 48h to 72h before being handled. Otherwise the swimsuits would lose shape !

The fabric is then stacked in layers of 20 to optimize production during cutting.

Next Stop the production workshop !

Everybody to your machines, it’s time to start assembling! Here, there is no supply chain. The seamstresses follow their pieces. An osteopath visits regularly to give them muscular warm-up and to prevent sickness. But that’s not all! An ergonomist is also in charge of adapting the working environment so that everyone is comfortable. What more could you ask for ?

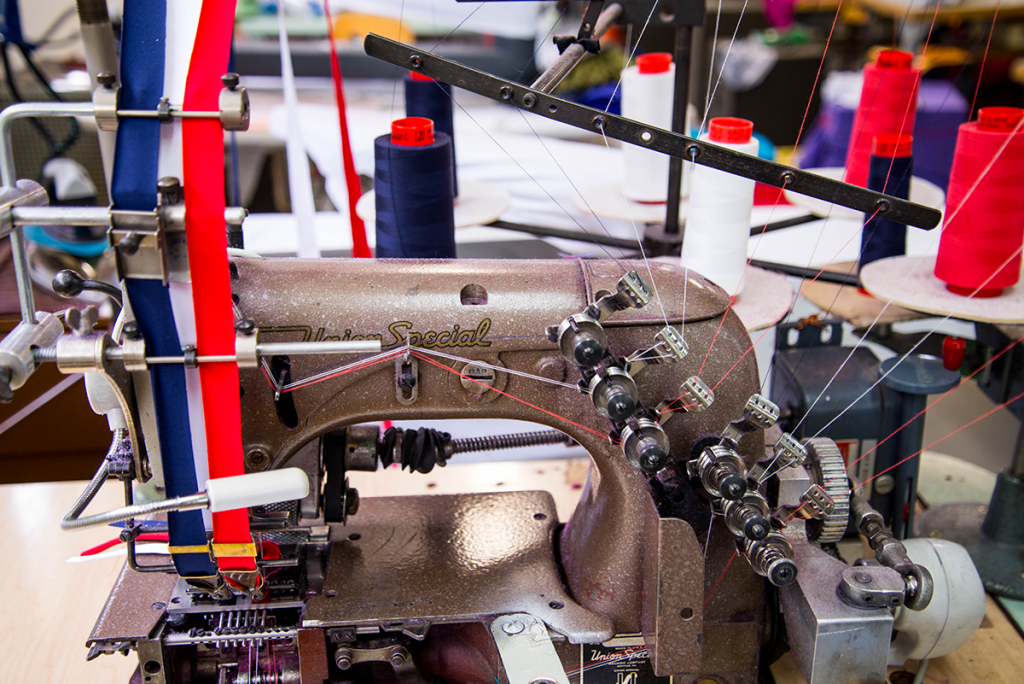

LA SLIP MACHINE !

We bought this machine 20 years ago, but it was never used. It was for making the stripes for Adidas. We brought it back 4 years ago for Le Slip Français. It was modified to sew 3 bands at a time! Matthieu Coquelin

25.000 swinsuits will be made this year just for Le Slip Français !

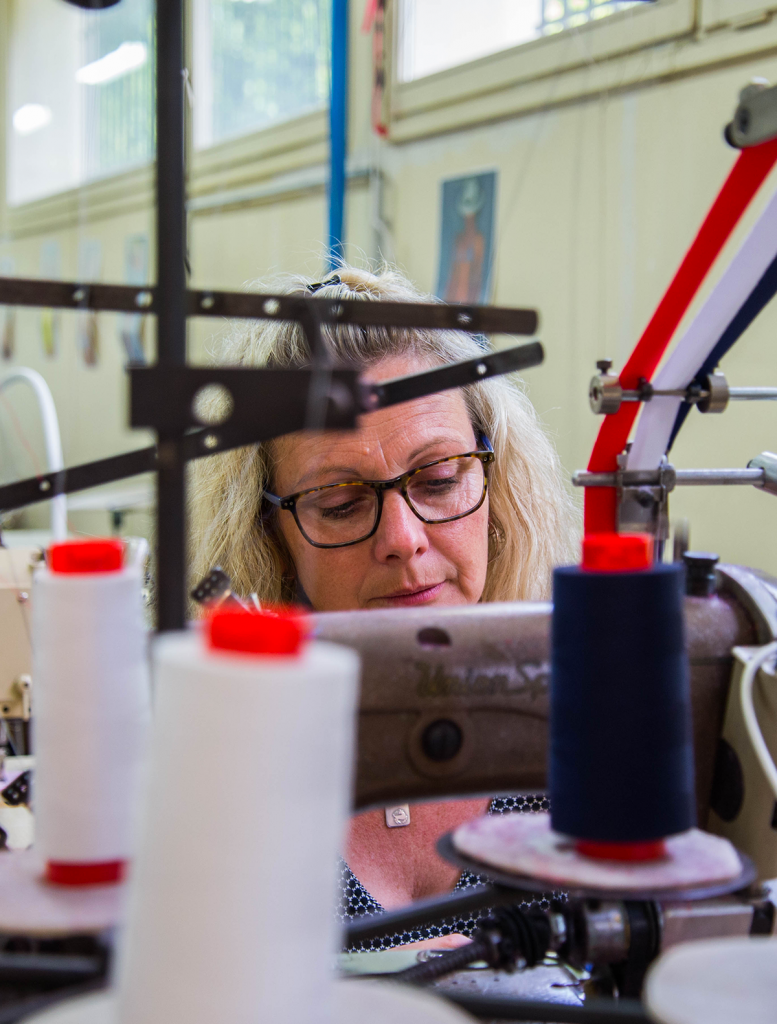

For 11 years, Rachel has been working in the factory of Coglais. She has been assigned to a management position: chef d’atelier. She is the one on the front line when orders come in. She makes the prototypes and the assembling. What’s left is to divide the work into groups the best way possible to get the order ready on time! At 45 years old, she is a woman full of life and proud of her job.

What do you like about your job ?

Le savoir-faire !

Creating an entire piece, knowing how it is made, step by step … It sure isn’t easy to work with this kind of elastic material. You can’t really press hard on it. The fingers’ humidity can influence the material too.

Your favorite piece ?

The shorts ! The collaboration with Le Slip Français is an amazing adventure! We had to come up with men’s swimsuits and look for ways to make them. It’s a different kind of work, the pieces are bigger also.

What does it take to become a good seamstress ?

The savoir-faire of course. We are all trained to use different sewing machines. An additional millimeter isn’t accepted here! You have to be very patient and always listen.

A few seconds in the embroider are just what it takes to make the 520 dots necessary to patch “Le Slip Français – Made in France”

The Quality Division !

This is where you shouldn’t miss out! We remeasure the swimming suits to be sure that there are no faults, we cut off (épluche) all the threads hanging (Yes that’s the term used. After 2 hours spent in the atelier, I started using their vocabulary!). A little bit of ironing and the swimsuits are ready to go. All packed and weighed !

Let’s go to the last step : the shipping !

Photographs: Alexis Chaillous for @thefrenchmakers